When it comes to metal fabrication, nothing has revolutionized the industry like the fiber laser cutting machine. But here’s the real kicker — how thick can it cut? And how fast can it go, depending on the power? Whether you’re a beginner or a seasoned professional, we’re diving deep into the practical aspects of fiber laser cutting, including thickness, speed, power, and performance.

Let’s unpack everything — from carbon steel and stainless steel thicknesses to cutting speeds across different laser powers. This guide breaks it all down so you can confidently pick the proper setup for your projects.

Table of Contents

- What Is a Fiber Laser Cutter?

- Why Fiber Lasers Are Dominating Metal Fabrication

- How Fiber Laser Power Impacts Cutting Performance

- Understanding Metal Thickness Limits

- Cutting Speeds Explained: From Thin to Thick

- Carbon Steel Cutting Parameters

- Stainless Steel Cutting Parameters

- The Role of Assist Gases in Cutting

- High-Power Laser Use Cases

- Low-to-Mid Power Fiber Lasers: Where They Shine

- Reflective Metals: Can Fiber Lasers Handle Them?

- Automation & Software in Fiber Cutting

- Cost Efficiency & Operating Expenses

- Safety and Environmental Benefits

- Choosing the Right Fiber Laser Cutter for Your Shop

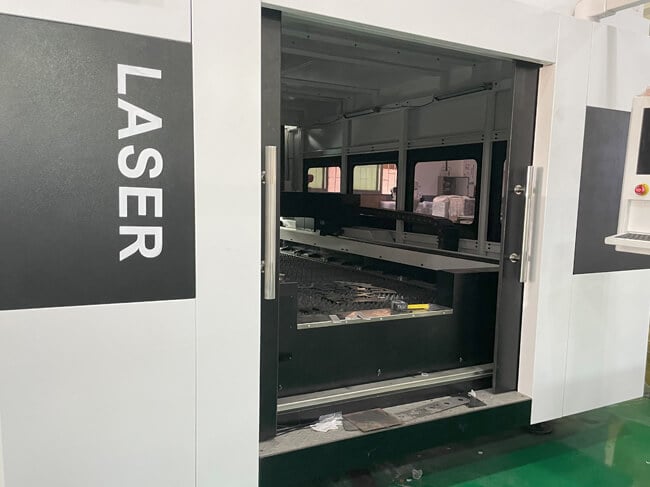

What Is a Fiber Laser Cutter?

A fiber laser cutter is a high-speed CNC-controlled cutting system that uses a focused laser beam to slice through metals with extreme precision. The magic? It uses a solid-state laser that’s transmitted via optical fiber — hence the name.

It’s not just about sharp edges and precision, though. Fiber lasers are also characterized by their efficiency, consistency, and cleaner operations. Unlike plasma or waterjet cutters, they don’t need frequent maintenance or consumables.

Why Fiber Lasers Are Dominating Metal Fabrication

We’ve seen the evolution: from plasma and waterjet machines to CO2 and YAG lasers. Fiber lasers are now at the top because:

- Fewer consumables required

- Higher cutting speeds

- Longer operational life

- Ability to cut reflective and hard metals

- Better energy efficiency

It’s like upgrading from a flip phone to a smartphone — you get more power and options.

How Fiber Laser Power Impacts Cutting Performance

The higher the wattage, the deeper the laser can cut — but speed, precision, and material type also play huge roles. Here’s a quick breakdown:

Power Range & Capabilities:

- 1500W–4000W: Ideal for thin sheet metal (up to ~16mm carbon steel)

- 6000W–12000W: Handles mid-range thicknesses efficiently

- 15000W–30000W: For industrial-grade thicknesses (up to 60 mm+)

- 40000W–60000W: Extreme cutting depth (up to 100mm+), great for structural steel

Understanding Metal Thickness Limits

Yes, fiber lasers can cut over 100mm of carbon steel. But that’s not always the norm, especially in smaller fabrication shops.

| Laser Power | Max Carbon Steel Thickness |

| 1500W | 6mm – 12mm |

| 3000W | Up to 20mm |

| 6000W | 25mm – 38mm |

| 12000W | 50mm – 60mm |

| 30000W | 70mm – 100mm+ |

| 60000W | Up to 120mm+ |

Cutting Speeds Explained: From Thin to Thick

Speed depends on power, gas, and thickness. Let’s illustrate this with real examples.

At 1500W (Air):

- 1mm carbon steel: 12–15 m/min

- 5mm carbon steel: 2.3–4.5 m/min

- 10mm carbon steel: 1.0–2.2 m/min

At 12000W (Oxygen):

- 30mm carbon steel: 1.2–1.3 m/min

- 50mm carbon steel: 0.8–1.2 m/min

Carbon Steel Cutting Parameters

Low to Mid Power (1500W – 4000W)

- Gas Options: Air, Oxygen, Nitrogen

- Max Thickness: ~20mm

- Applications: Automotive, appliances, signage

High Power (6000W – 30000W)

- Gas Options: Air, Nitrogen, O2

- Max Thickness: ~70mm

- Applications: Shipbuilding, machinery, bridges

Ultra High Power (40000W – 60000W)

- Max Thickness: 100 mm+

- Speed: 0.6 to 32 m/min, depending on material

- Gas Mixes: N2/O2 combo and air

Stainless Steel Cutting Parameters

Stainless steel is trickier due to reflectivity and alloy content.

| Power (W) | Thickness | Speed (m/min) |

| 1500W | 1–3mm | 5–15 m/min |

| 3000W | 5–8mm | 2–7 m/min |

| 6000W | 10–16mm | 1–3 m/min |

| 12000W | 20–30mm | 0.5–2.5 m/min |

| 30000W | 35–50mm | 0.4–1.5 m/min |

The Role of Assist Gases in Cutting

Gases aren’t just for show. They directly affect cutting performance:

- Air: Cost-effective, okay for mild steel

- Oxygen (O₂): Boosts speed, especially in thicker carbon steel

- Nitrogen (N₂): Delivers cleaner cuts on stainless and aluminum

Pro Tip: Thicker materials benefit from oxygen’s burning assist, while stainless and aluminum demand nitrogen to prevent edge discoloration.

High-Power Laser Use Cases

You’ll need higher wattage if you’re cutting:

- Thick carbon or stainless plates (30 mm+)

- Structural steel for construction

- Parts with low tolerance for dross or bevel

It’s the go-to for:

- Aerospace parts

- Ship hulls

- Oil rig components

Low-to-Mid Power Fiber Lasers: Where They Shine

If you’re into signage, kitchenware, or automotive parts, don’t overpay for 30kW machines.

Benefits of lower power:

- Lower upfront cost

- Easier to maintain

- Great precision on thin materials

Reflective Metals: Can Fiber Lasers Handle Them?

Short answer: Yes!

Fiber lasers can cut brass, copper, aluminum, gold, and even silver — all notoriously reflective materials. Just use the correct wavelengths and gas setups (mostly nitrogen) and watch those sparks fly.

Automation & Software in Fiber Cutting

Modern fiber lasers come with:

- CAD/CAM compatibility

- Nesting software

- Remote monitoring

- AI-driven focus control

These features streamline mass production and reduce labor costs.

Cost Efficiency & Operating Expenses

Unlike plasma or CO2 cutters, fiber lasers:

- Consume less energy

- Have fewer consumables

- Require minimal maintenance

Bottom line: Higher upfront cost, lower long-term expense.

Safety and Environmental Benefits

Fiber lasers don’t need chemicals or high-pressure water. That means:

- No toxic waste

- Cleaner air

- Safer for operators

Plus, less mess = less cleanup.

Choosing the Right Fiber Laser Cutter for Your Shop

Ask yourself:

- What materials will I cut most often?

- How thick are those materials?

- Do I need speed or precision?

- What’s my budget?

Then match that with the correct power level, gas setup, and automation features.

Conclusion

Fiber laser cutters are powerhouses — versatile, efficient, and capable of cutting up to 100 mm+ of carbon steel with the proper wattage and gas combo. Whether you’re a job shop handling custom signage or a manufacturer producing heavy-duty steel components, there’s a fiber laser setup tailored just for you.

FAQs

1. How thick can a 1500W fiber laser cut?

Typically, up to 5mm carbon steel or 3mm stainless steel with moderate speed.

2. What is the best gas for cutting stainless steel?

Nitrogen is ideal as it prevents discoloration and provides clean edges.

3. Can fiber lasers cut aluminum and brass?

Yes, with proper settings and the right gas, they can easily handle reflective metals.

4. How fast can a fiber laser cut 10mm carbon steel?

Speeds range from 1 to 2.2 m/min, depending on the power and gas used.

5. Are fiber laser cutters eco-friendly?

Absolutely — they don’t use consumables or chemicals, reducing waste and emissions.