In the competitive sign-making industry, precision, speed, and consistency are key to success. Traditional manual bending methods have long limited production efficiency — until Varisigns introduced its state-of-the-art letter bending machines. Globally recognized for engineering excellence, these machines streamline 3D sign fabrication, turning raw metal coils into flawless letter returns with automated precision.

What Is a Varisigns Letter Bending Machine?

A Varisigns letter bending machine is an advanced CNC-controlled device designed to bend aluminum, stainless steel, copper, and other metal strips into the sidewalls (returns) of channel letters. Integrated with servo motors, precision feeding systems, and intelligent software, it replaces manual bending and delivers superior accuracy at high speed.

Varisigns offers multiple models, ranging from the entry-level VAM-S1 to the industrial-grade channel bender machine VAM-S18, which are compatible with design files from CorelDRAW, AutoCAD, and Adobe Illustrator, supporting DXF, PLT, and AI formats.

Why Varisigns Leads the Channel Letter Industry

- Proprietary software with English interface for intuitive control

- High precision (±0.1mm) with servo-driven systems

- Multi-material compatibility, including aluminum, stainless steel, and galvanized steel

- 24/7 technical support and video tutorials

- Durable hardware for industrial use

Key Features of the Varisigns Letter Bending Machine

1. Dual-Axis Servo Control for Unmatched Accuracy

The dual-axis servo system ensures consistent feeding, precise corner angles, and clean bends, eliminating human error common in manual bending.

2. Intelligent Software Integration

Varisigns channel letter machine software reads vector design files (AI, DXF, PLT) and converts them into bending commands, including simulation previews for zero material waste.

3. Multi-Material Processing Capability

Handles aluminum (0.4–1.5mm), stainless steel (up to 2.0mm), copper, and galvanized steel, suitable for indoor and outdoor signage.

4. Fast Bending Speed for Higher Throughput

Automated feeding achieves speeds up to 15 meters per minute, drastically reducing production time.

5. Robust Frame and Structural Design

Heavy-duty casting minimizes vibration and maintains calibration over years of continuous use.

6. User-Friendly Interface and Training

Intuitive interface, tutorial videos, remote training, and lifetime technical support ensure smooth operation.

Varisigns Model Lineup

VAM-S1 – Entry-Level Precision

- Coil width: 20–130mm

- Thickness: ≤1.5mm

- Accuracy: ±0.1mm

- Best for start-up companies to make aluminum channel letters only

VAM-S18 – Heavy-Duty Industrial Performance

- Coil width: 25–200mm

- Thickness: ≤1.5mm

- Materials: Aluminum, steel, stainless, copper

- Best for large outdoor signage, trim cap 3d letters and industrial-grade fabrication

How the Varisigns Machine Streamlines Your Workflow

- Design Creation in AI, PLT, or DXF format

- File Import into Varisigns software

- Parameter Setup: coil material, width, and bending depth

- Simulation Preview

- Automatic Feeding

- Bending Execution via servo motors

- Output Completion: ready for welding or assembly

Advantages of Using a Varisigns Letter Bending Machine

- Increased production efficiency

- Unmatched consistency

- Cost savings on labor and materials

- Expanded design capabilities

- Long-term reliability

Practical Tips for Maximizing ROI

- Train operators thoroughly

- Maintain regular calibration

- Use quality metal coils

- Integrate with cutting and welding equipment

- Keep spare parts on hand

Real-World Applications

- Storefront and building signage

- LED channel letters

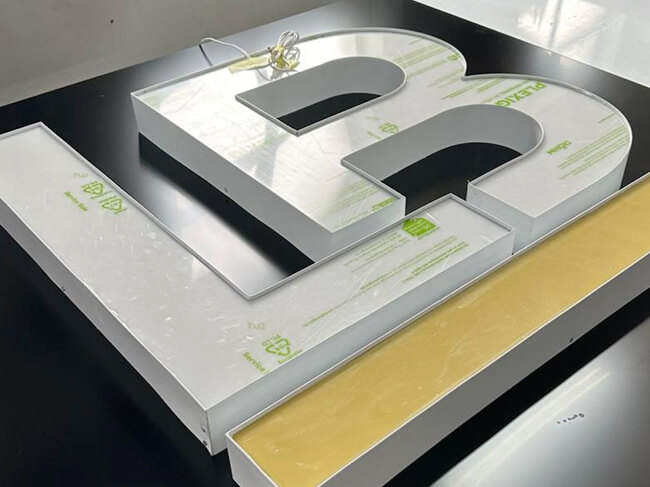

- Acrylic-faced letters with metal returns

- Corporate branding and retail displays

- Architectural 3D lettering

Comparing Varisigns to Competitors

| Feature | Varisigns | Generic Machines |

|---|---|---|

| Precision | ±0.1mm | ±0.3–0.5mm |

| Software Support | AI, DXF, PLT | Limited |

| Material Range | Aluminum, stainless, copper | Aluminum only |

| After-Sales Service | 24/7 global support | Limited |

| Training Resources | Tutorials & remote sessions | Minimal documentation |

| Machine Longevity | 8–10 years | 3–5 years |

FAQ

What is a Varisigns letter bending machine?

It is a CNC-controlled device that bends metal strips into 3D channel letters with precision, speed, and multi-material support.

Which Varisigns model is best for small sign shops?

The VAM-S1 is ideal for small to mid-size shops, handling coil widths up to 130mm and thickness up to 1.5mm.

Can a Varisigns machine bend large outdoor letters?

Yes, the VAM-S18 can bend coil widths up to 200mm and thicknesses up to 1.5mm, perfect for large outdoor signage. Can do small and big letters from 2.4” to 15ft tall.

How accurate are Varisigns letter benders?

They offer ±0.1mm accuracy, ensuring consistent letter shapes and precise angles.

What materials can Varisigns machines bend?

Aluminum, stainless steel, copper, brass, and galvanized steel.

Does Varisigns provide training and support?

Yes, including video tutorials, remote training, and 24/7 technical support.

Is a Varisigns letter bending machine worth the investment?

For shops aiming to increase efficiency, precision, and scalability, it is a long-term investment that boosts quality and reduces labor costs.